Leather is one of the most durable and versatile materials that has been in use for centuries. It is widely used in various industries such as fashion, automotive, and furniture. In India, Kanpur and Kolkata are two major hubs for leather production. While both cities are renowned for their leather products, there are some key differences between Kanpur leather and Kolkata leather. In this blog, we'll take a closer look at the battle of the leathers and determine which one reigns supreme.

Kanpur Leather

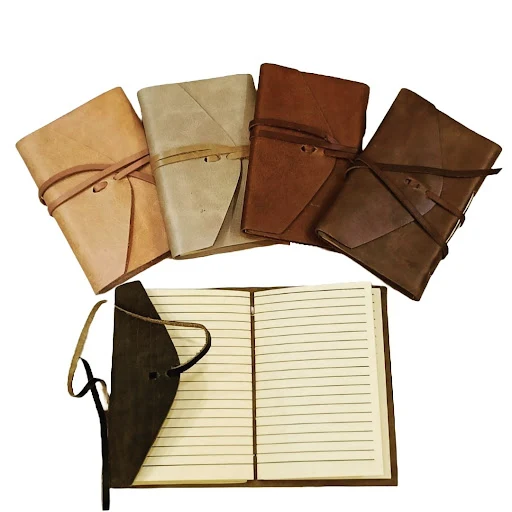

Kanpur is known for its high-quality leather products. The city has a long history of producing leather, dating back to the British colonial period. The leather produced in Kanpur is known for its strength, durability, and resistance to wear and tear. Kanpur leather is made using a combination of chrome and vegetable tanning, which gives it a unique texture and feel. The use of chrome tanning makes the leather more water-resistant, while vegetable tanning gives it a natural look and feel.

Kolkata Leather

Kolkata is also a major hub for leather production in India. The city has a rich history of leather production, dating back to the British colonial period. Kolkata is known for producing high-quality leather products, including shoes, bags, and jackets. The leather produced in Kolkata is known for its softness and flexibility. Kolkata leather is made using vegetable tanning, which gives it a natural look and feel. The leather is also treated with oils and waxes, which makes it softer and more pliable.

Comparison

When it comes to strength and durability, Kanpur leather has an edge over Kolkata leather. The combination of chrome and vegetable tanning used in Kanpur leather production gives it superior strength and resistance to wear and tear. On the other hand, Kolkata leather is known for its softness and flexibility. It is a more comfortable material to wear and is often used in luxury leather products.

In terms of production processes, Kanpur leather is processed using a combination of chrome and vegetable tanning, while Kolkata leather relies solely on vegetable tanning. The use of chrome tanning in Kanpur leather production makes it more water-resistant, while vegetable tanning used in Kolkata leather production makes it more eco-friendly.

Overall, both Kanpur and Kolkata leather have their own unique characteristics and qualities. Consumers can choose between the two based on their personal preferences and requirements. If you are looking for strength and durability, Kanpur leather may be the better choice. If you are looking for a softer and more flexible material, Kolkata leather may be the way to go.

In conclusion, the battle of the leathers between Kanpur and Kolkata is a close one. Each city has its own strengths and qualities that make their leather unique. It ultimately depends on the individual consumer's needs and preferences when deciding which leather reigns supreme.

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)